- Home

- >

- News

- >

- Product Information

- >

News

As RV travel becomes an increasingly popular choice, ensuring power needs during trips is a key concern for every RV user. While traditional fuel generators can solve power issues, they are noisy, polluting, and costly to operate.

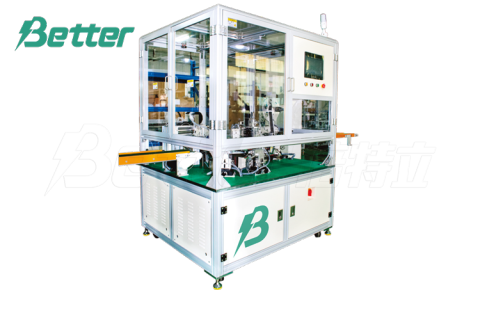

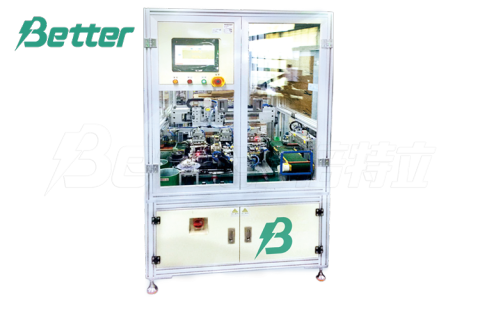

This article explores how to integrate the protective plate adhesive bending machine into existing production lines and optimize its operation to further enhance the overall performance of the production line.

In today's world, electricity has become the lifeblood of our lives and work. Whether in households, businesses, or industrial applications, a stable and reliable power supply is crucial.

In industrial production, the enhancement of product quality is closely linked to precise and efficient testing equipment. The high-precision performance testing machine, with its outstanding detection capabilities, helps manufacturers ensure high quality and reliability of their products.

With the growing awareness of environmental protection and advancements in renewable energy technology,

Whether due to weather-related extended power outages or shortages in electricity supply, families always need a stable backup power source.

As global manufacturing demands continue to rise in terms of both production efficiency and product quality, the use of automatic material collection machines has gradually become an essential tool for increasing automation levels on production lines.

With the rapid global advancement of technology, battery innovations are continually emerging, especially in the field of transportation. In Africa, motorcycles serve as one of the primary modes of transportation, making the performance of their battery systems crucial for daily life and economic activities.

In the context of Industry 4.0, intelligence, automation, and precision have become the mainstream trends in the manufacturing industry.

As the name suggests, a home wall-mounted energy storage system is an energy storage device installed on the wall of a household. It is primarily used to store renewable energy such as solar and wind power, converting it into electricity for daily household use.

The double-sided labeling machine, with its advanced low-energy design, offers an efficient and eco-friendly labeling solution for companies.