Advanced Dimensional Testing Machine: Core Equipment for Industrial Intelligent Quality Inspection

2024-10-22 18:00Table of Contents

Advanced Dimensional Testing Machine: Core Equipment for Industrial Intelligent Quality Inspection

Equipment Highlights and Technical Features

Functional Highlights

Key Technical Parameters

Operation Process and User Guide

Applicable Industries and Application Solutions

Automotive Manufacturing

Home Appliance Manufacturing

Precision Tool Manufacturing

Biomedical Device Manufacturing

Case Studies

Case 1: A Well-Known Automotive Manufacturer

Case 2: A Global Home Appliance Brand

Future Trends Outlook

Frequently Asked Questions (FAQ)

Conclusion

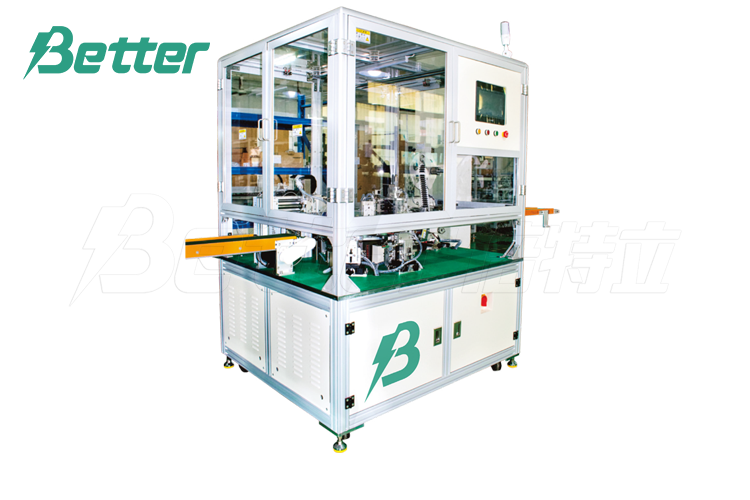

Product Overview

In the context of Industry 4.0, intelligence, automation, and precision have become the mainstream trends in the manufacturing industry. The Advanced Dimensional Testing Machine has become indispensable in industrial production lines due to its efficient, precise, and intelligent testing capabilities. This article will deeply explore the machine’s functional highlights, technical features, application scenarios, and future development trends, showcasing its significant value in industrial production.

Equipment Highlights and Technical Features

Functional Highlights

Ultra-High Precision Testing

The Advanced Dimensional Testing Machine adopts cutting-edge optical measurement technology and highly sensitive sensors to achieve sub-micron precision. Its excellent accuracy ensures that every product on the production line meets the strictest standards.

Fully Automated Operation

The machine’s fully automated design allows it to operate continuously without manual intervention. The entire process, from feeding, testing, to sorting, is automatically completed, significantly improving production efficiency.

Intelligent Data Analysis

Equipped with a powerful data analysis system, the machine can process and store test data in real time, generating detailed quality reports. These data can provide strong decision support for production management, helping companies optimize their production processes.

Versatile Adaptability

The machine is suitable for testing products made from various materials and with different specifications. Users can flexibly adjust the testing parameters to meet specific production requirements.

Remote Control and Maintenance

The machine supports remote control functions, allowing users to monitor the machine’s status in real-time through the network, perform remote debugging, and carry out maintenance, reducing downtime caused by equipment failures.

Key Technical Parameters

Transmission Size (Tj/mm): L: 40-120, W: 35-90, T: 3-8

Measurement Accuracy: ±0.01mm

Detection Speed: 1500 PCS/H

Operating Pressure: 0.5 MPa

Equipment Power: 2KW

Operating Environment: Temperature 0~50℃, Humidity 30%~95%

Power Requirements: 220V 50Hz

Equipment Dimensions: 1400×1290×1900 mm

Operation Process and User Guide

Product Feeding

The products to be tested are fed into the machine via an automated feeding system, which will automatically initiate the testing process.

High-Precision Testing

The machine uses optical sensors and highly sensitive measurement systems to perform precise measurements of the products, recording dimensional data in real time.

Intelligent Data Analysis and Sorting

The system automatically analyzes the data and sorts out non-compliant products based on preset standards, ensuring that only qualified products proceed down the production line.

Remote Monitoring and Maintenance

Users can monitor the machine's status through remote control features, perform online debugging, and carry out remote maintenance.

Applicable Industries and Application Solutions

1. Automotive Manufacturing

In the automotive industry, the dimensional precision of parts directly affects the vehicle's performance and safety. The Advanced Dimensional Testing Machine can efficiently test the dimensions of automotive components, ensuring that every part meets design standards, thereby improving overall vehicle quality.

2. Home Appliance Manufacturing

In home appliance manufacturing, dimensional accuracy is critical to ensuring product reliability and lifespan. The Advanced Dimensional Testing Machine helps manufacturers control product quality through precise testing, reducing defect rates.

3. Precision Tool Manufacturing

Dimensional errors in precision tools directly impact their functionality and durability. This machine can accurately test the dimensions of various precision tools, ensuring they meet stringent industry standards.

4. Biomedical Device Manufacturing

Biomedical devices, particularly implantable devices and minimally invasive surgical instruments, have extremely high dimensional accuracy requirements. The Advanced Dimensional Testing Machine provides strong quality assurance for the production of these high-precision devices.

Case Studies

Case 1: A Well-Known Automotive Manufacturer

A well-known automotive manufacturer introduced the Advanced Dimensional Testing Machine into its new electric vehicle production line. The machine’s high-precision testing capabilities ensured the dimensional consistency of battery modules and key components, enhancing vehicle performance and safety.

Case 2: A Global Home Appliance Brand

A leading global home appliance brand utilized the Advanced Dimensional Testing Machine in the production line for its new refrigerator model. The precise testing significantly reduced defect rates, increased production efficiency, and gained a larger market share.

Future Trends Outlook

With the acceleration of industrial intelligence, the Advanced Dimensional Testing Machine will continue to play a key role in high-precision testing. In the future, this equipment will further integrate AI technologies, enabling smarter data analysis and decision-making support. Additionally, with the widespread adoption of the industrial Internet of Things (IoT), the machine’s remote control and real-time monitoring capabilities will be further enhanced, helping enterprises achieve comprehensive intelligent production management.

Frequently Asked Questions (FAQ)

What industries is this equipment suitable for?

The Advanced Dimensional Testing Machine is suitable for industries such as automotive manufacturing, home appliance manufacturing, precision tool manufacturing, and biomedical device manufacturing.

What is the measurement accuracy of the machine?

The measurement accuracy is ±0.01mm, meeting the needs of high-precision industrial manufacturing.

How is remote control and maintenance conducted?

The machine supports remote control functions, allowing users to monitor the equipment status in real-time through the network, conduct remote debugging, and perform maintenance, ensuring continuous efficient operation.

Can the machine test products made from different materials?

Yes, the machine supports testing products made from various materials. Users can adjust the testing parameters according to production requirements.

Is the operation complex?

The machine is designed with user-friendliness in mind, featuring a simple and intuitive interface. With minimal training, users can operate the machine proficiently.

Conclusion

With its outstanding precision, fully automated operation, and intelligent data analysis capabilities, the Advanced Dimensional Testing Machine has become a key piece of equipment for improving quality control across various industries. As industrial intelligence continues to advance, this machine will play an increasingly critical role, providing robust support for high-quality production and enhancing market competitiveness for enterprises.