- Home

- >

- News

- >

- Product Information

- >

News

Sealed lead-acid (SLA) batteries are widely used in various applications, including backup power systems, electric vehicles, and industrial machinery.

The battery manufacturing process consists of several crucial stages, each requiring precision and efficiency to ensure high-quality output

Before initiating a battery production facility, it is essential to understand the various stages of lead acid battery manufacturing. The core processes include:

Setting up a battery manufacturing plant requires careful planning, the right equipment, and efficient production processes.

Lead-acid batteries have been the go-to solution for many energy storage needs for more than a century, thanks to their reliability, cost-effectiveness, and long-lasting performance.

Lead-acid batteries have been in use for more than a century and continue to be an essential technology in various applications, from powering vehicles to providing backup energy storage.

Battery manufacturing plays a pivotal role in the global economy, as batteries power everything from household electronics to electric vehicles and renewable energy systems.

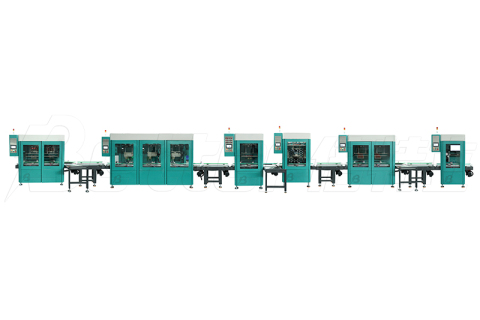

In response to these pain points, the automated AGM Enveloping and Stacking Machine has emerged, offering battery manufacturing companies a complete, intelligent, and precise production solution.

The Better Tech 1020kWh integrated unit uses advanced lithium iron phosphate battery technology, offering the advantage of high energy density.