High-Precision Performance Testing Machine: A Reliable Partner for Ensuring Product Quality

2024-10-24 18:00

Table of Contents

Overview of the High-Precision Performance Testing Machine

Functions and Technical Features

Key Features

Technical Specifications

Operating Procedure and User Guide

Applicable Industries and Use Cases

Battery Manufacturing

Electronic Component Testing

Automotive Parts Inspection

Industrial Automation Systems

Real-World Application Scenarios

Scenario 1: Battery Manufacturing Workshop

Scenario 2: Automotive Parts Inspection

Future Development and Technical Outlook

Frequently Asked Questions (FAQ)

Conclusion

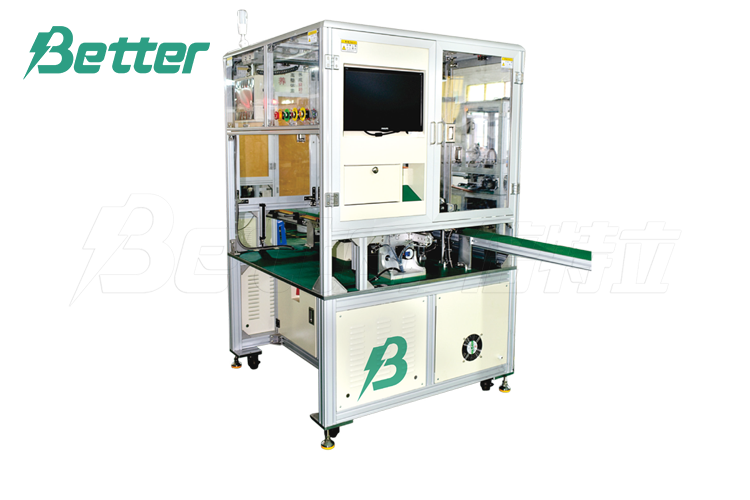

Overview of the High-Precision Performance Testing Machine

In industrial production, the enhancement of product quality is closely linked to precise and efficient testing equipment. The high-precision performance testing machine, with its outstanding detection capabilities, helps manufacturers ensure high quality and reliability of their products. This article introduces the key features, technical specifications, applicable industries, and real-world application scenarios of this performance testing machine, showcasing how it has become a reliable partner in improving product quality for enterprises.

Functions and Technical Features

Key Features

High-Precision Testing: Equipped with advanced sensors and measuring systems, the machine achieves micron-level precision in performance testing, ensuring that every product meets strict quality standards.

Multi-Functional Testing Capabilities: The high-precision performance testing machine supports a variety of testing items, including voltage, resistance, short circuit, and discharge tests, enabling comprehensive performance assessments to ensure stability and safety under various usage conditions.

Automated Operating System: The machine supports fully automated operation, from material loading to testing and sorting, requiring no manual intervention throughout the process. This significantly increases production efficiency and reduces the risk of human errors.

Real-Time Data Analysis and Storage: Built with a high-speed data processing system, the machine analyzes test data in real-time and stores it in a database, generating detailed test reports for production managers to review at any time.

Flexible Configuration and Easy Maintenance: The machine supports various configurations, allowing for quick adjustments to meet different product requirements. Its simple design makes maintenance easy, reducing downtime.

Technical Specifications

Transmission Size (Tj/mm): L:40-120 W:35-90 T:3-10

Test Accuracy: Simulated test accuracy of ±0.5%

Air Pressure Requirement: 0.5MPa

Operating Temperature: 0~50°C, Humidity 30%~95%

Equipment Power: 3KW

Power Supply Requirements: 220V 50Hz

Testing Speed: 1200 pieces/hour

Equipment Dimensions: 1200×1290×1990mm

Operating Procedure and User Guide

To ensure optimal performance of the high-precision performance testing machine, follow the standard operating procedure outlined below:

Product Loading: Use the automated loading system to feed the products to be tested into the machine. The equipment will automatically begin the testing process.

Performance Testing: The machine automatically performs various performance tests based on the preset criteria and records real-time data.

Data Analysis and Sorting: The system analyzes the test data automatically and sorts out any defective products, ensuring that only qualified products proceed to the next production stage.

Data Storage and Report Generation: After testing, the system generates detailed test reports and stores the data in a database for future reference and analysis.

Equipment Maintenance and Troubleshooting: The machine supports remote monitoring and maintenance, allowing users to check the equipment status in real-time and conduct online adjustments and troubleshooting.

Applicable Industries and Use Cases

Battery Manufacturing

In battery production, stability and consistency of performance are crucial to ensuring product quality. The high-precision performance testing machine comprehensively tests various performance indicators of batteries, ensuring each one meets design standards.

Electronic Component Testing

The performance of electronic components directly impacts the overall quality of electronic products. The high-precision performance testing machine can conduct comprehensive tests on a wide range of electronic components, ensuring reliability in complex circuits.

Automotive Parts Inspection

The precision and performance of automotive parts directly affect the safety and durability of vehicles. The high-precision performance testing machine is capable of accurately inspecting critical parts, ensuring compliance with stringent automotive industry standards.

Industrial Automation Systems

In industrial automation systems, the stability of sensors and control modules is critical to the reliable operation of the entire system. The high-precision performance testing machine can test these modules' performance, ensuring the stability and reliability of the overall system.

Real-World Application Scenarios

Scenario 1: Battery Manufacturing Workshop

In a large battery manufacturing plant, the high-precision performance testing machine is used for lithium battery production testing. The machine's high-precision testing ensures battery safety and consistency, allowing the production line to operate efficiently and reducing the defect rate.

Scenario 2: Automotive Parts Inspection

In a production workshop of an automotive parts supplier, the high-precision performance testing machine is used to inspect the performance of engine control modules. The machine's efficient testing capabilities help ensure that every part meets the automotive industry's stringent standards, enhancing vehicle quality.

Future Development and Technical Outlook

With the advancement of Industry 4.0, the high-precision performance testing machine will continue to play a key role in smart manufacturing. In the future, the machine will further improve in terms of testing precision and speed, while incorporating more intelligent features, such as AI algorithms and machine learning, to achieve more accurate data analysis and production optimization. Additionally, as the Industrial Internet of Things (IIoT) evolves, the machine's remote monitoring and maintenance capabilities will become more refined, providing enterprises with more efficient and intelligent production solutions.

Frequently Asked Questions (FAQ)

Which industries is the high-precision performance testing machine suitable for?

The machine is suitable for battery manufacturing, electronic component testing, automotive parts inspection, and industrial automation systems.

What is the machine's testing accuracy?

The testing accuracy of the high-precision performance testing machine is ±0.5%, meeting the requirements for high-precision manufacturing.

Is the machine maintenance-intensive?

The machine requires relatively low maintenance. Regular maintenance mainly involves cleaning sensors, checking system calibration, and updating software.

Does the machine support testing products of different specifications?

Yes, the machine supports testing a variety of product specifications, with adjustable parameters based on user requirements.

Does the machine support remote monitoring and maintenance?

Yes, the machine supports remote monitoring and maintenance. Users can check the equipment status in real-time via the network and perform online troubleshooting.

Conclusion

The high-precision performance testing machine, with its exceptional detection accuracy, fully automated operation, and intelligent data analysis capabilities, has become a reliable partner in enhancing product quality across various manufacturing industries. As technology continues to advance, the machine will play an increasingly important role in more industries, providing enterprises with efficient and precise quality control solutions.