Dimension testing machine: The Perfect Combination of Precision Detection and Automated Production

2024-09-16 18:00Table of Contents

· Introduction

· Product Features and Technical Specifications

o Functional Characteristics

o Technical Parameters

· Operation Process and User Guide

· Application Scenarios and Industry Solutions

o Lithium Battery Production

o Semiconductor Component Manufacturing

o Precision Mechanical Processing

o Medical Equipment Production

· Case Studies

o Case 1: A Renowned Electronics Manufacturer

o Case 2: An International Automotive Parts Supplier

· Future Development Directions and Market Prospects

· Frequently Asked Questions (FAQ)

· Conclusion

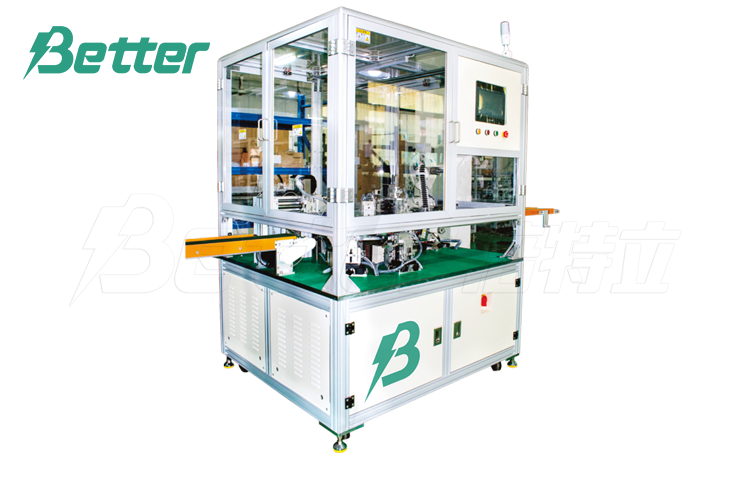

Product Overview

In today’s manufacturing industry, intelligence and automation have become key factors in improving production efficiency and ensuring product quality. To meet the high demands for precision and efficiency on modern production lines, the Dimension testing machine was developed. This device not only achieves high-precision dimensional inspection but also boasts advanced automation and intelligent data processing capabilities. This article will detail the features, technical specifications, application scenarios, and future development directions of this equipment.

Product Features and Technical Specifications

Functional Characteristics

·

Intelligent Detection: The Dimension testing machine employs advanced sensor technology and AI algorithms to perform high-precision measurements of product dimensions and automatically identify anomalies. This intelligent function significantly reduces manual errors and enhances overall production line efficiency.

·

·

Automated Operation: From product feeding, measurement to result analysis, the entire process is automated by the system, achieving full-process automation. The device supports 24-hour continuous operation, making it suitable for high-intensity production environments.

·

·

Real-Time Data Processing: Equipped with a powerful data processing system, the device can record and analyze measurement data in real time, generating detailed statistical reports. This data can be used to optimize production processes and enhance product quality control.

·

·

Flexible Adaptability: The Dimension testing machine supports testing of various product specifications. Users can quickly adjust testing parameters according to different production needs, allowing for flexible adaptation to diverse production tasks.

·

·

Remote Monitoring and Maintenance: The device supports remote monitoring, enabling users to view the operational status in real-time over the network and perform remote debugging and maintenance. This feature greatly reduces downtime caused by equipment failures.

·

Technical Parameters

· Transmission Size (Tj/mm): L:40-120, W:35-90, T:3-8

· Length, Width, and Thickness Measurement Accuracy: ±0.02mm

· Detection Speed: 1500 PCS/H

· Data Processing Accuracy: 0.5 MPa

· Equipment Power: 2 KW

· Operating Environment Temperature: 0~50°C, Humidity: 30%~95%

· Power Requirements: 220V 50Hz

· Equipment Dimensions: 1400 × 1290 × 1900 mm

Operation Process and User Guide

The Dimension testing machine's operation process is straightforward and suitable for various industrial applications. Below is the standard operation process for the device:

1. Product Feeding: The product to be measured is fed into the testing machine via the automatic feeding system.

2. Precision Measurement: The device automatically begins measuring the product’s dimensions and records the data in real time.

3. Data Analysis and Judgment: The system automatically determines whether the product meets the standards based on preset criteria and generates a measurement report.

4. Automatic Sorting: Non-conforming products are automatically sorted out, ensuring that only products meeting standards proceed to the next process.

5. Data Storage and Feedback: After testing, all data is uploaded to the cloud for further analysis and optimization by production managers.

Application Scenarios and Industry Solutions

·

Lithium Battery Production: In lithium battery production, dimensional accuracy directly impacts battery performance. The Dimension testing machine plays a vital role on the production line, ensuring that each battery meets stringent design standards.

·

·

Semiconductor Component Manufacturing: Semiconductor component manufacturing requires extremely high dimensional accuracy. The Dimension testing machine provides reliable quality assurance for semiconductor production through its high-precision measurement capabilities.

·

·

Precision Mechanical Processing: In precision mechanical processing, part dimensions directly affect the performance of the entire machine. The device can be used to measure various mechanical parts to ensure they fit accurately during assembly.

·

·

Medical Equipment Production: Safety and precision are critical in medical equipment production. The Dimension testing machine checks key dimensions of medical instruments to ensure they meet strict industry standards, protecting patient safety.

·

Case Studies

·

Case 1: A Renowned Electronics Manufacturer

·

o This electronics manufacturer implemented the Dimension testing machine for inspecting new chip production. The device’s efficient measurement capabilities and real-time data analysis helped the manufacturer boost production efficiency and maintain high product quality, earning widespread customer praise.

·

Case 2: An International Automotive Parts Supplier

·

o This automotive parts supplier applied the Dimension testing machine on their production line to inspect critical components. The device’s high-precision measurements and automated operations significantly reduced the defect rate and enhanced production efficiency.

Future Development Directions and Market Prospects

With the growing demand for intelligence and automation in manufacturing, the application prospects for Dimension testing machines are very promising. In the future, the equipment will continue to develop towards higher precision, stronger data processing capabilities, and more user-friendly operation experiences. As industrial IoT technologies advance, the Dimension testing machine will achieve closer integration with other production equipment, further enhancing the overall intelligence level of production lines.

Frequently Asked Questions (FAQ)

1. What industries are suitable for the Dimension testing machine?

· This equipment is suitable for multiple industries, including lithium battery production, semiconductor component manufacturing, precision mechanical processing, and medical equipment production.

2. What is the detection speed of the equipment?

· The standard detection speed of the equipment is 1500 PCS/H. The speed can be adjusted based on product specifications and testing requirements.

3. What are the maintenance requirements for the equipment?

· The equipment comes with remote monitoring and self-diagnostic functions, allowing users to monitor its status in real time via the network, reducing maintenance needs. Routine maintenance mainly includes cleaning sensors and calibrating the equipment.

4. Can the equipment accommodate different product specifications?

· Yes, the Dimension testing machine supports testing of various product specifications. Users can adjust the equipment through simple parameter settings to suit different product requirements.

5. Does the equipment support remote control and debugging?

· The equipment supports remote monitoring and debugging, allowing users to operate it remotely via the network, providing great convenience for managing large-scale production lines.

Conclusion

With its high precision, automation, and intelligent data processing capabilities, the Dimension testing machine serves as a valuable assistant in enhancing production efficiency and product quality across various manufacturing industries. As technology continues to advance, this equipment will be widely used in more industries, providing essential support for the intelligent development of manufacturing.