- Home

- >

News

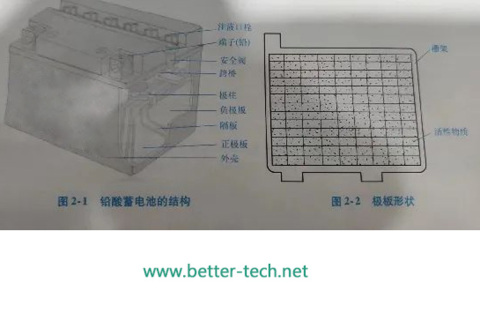

Lead-acid batteries are composed of important parts such as positive and negative plates, separators, plastic containers, poles and safety valve

Lead-acid battery production equipment is an important factor that affects the quality and performance of lead-acid batteries. It has various types for different purposes and processes, such as plate making machines, assembly machines, formation machines, etc.

In the production process of lead-acid batteries, the manufacturing process of positive and negative plates, electrolyte formula, battery molding and capacity detection will affect the service life of batteries

With more than ten years of exploration and innovation, Better Technology Group Limited has always been rooted in the battery manufacturing industry, from a single lead-acid battery manufacturing equipment supplier in the past to a "global battery manufacturing solution provider and full resource operator" with two main brands, BETTER and WELLPACK, providing valuable products and services to global users through technological innovation. We provide valuable products and services to customers worldwide through technological innovation.

Lead-acid batteries belong to the eighth category of dangerous goods, transportation requires a license, and export lead-acid batteries must be specially packaged (qualified packaging certificate), otherwise the customs will not pass.

This means that Better Group's existing management system, product quality, environmental quality, etc. have been recognized by the International Organization for Standardization, which could meet the product quality requirements and standards of the international market, and continuously and steadily provide customers with high quality products and high quality services. This is another very important milestone in the development process of Better Goup.

What is the real life of lithium iron phosphate? In fact, the life of a lithium battery pack is nearly the same, whether it is lithium iron phosphate battery or ternary lithium battery, the real service life is related to the user's method and protection. In this article, let's talk about what is the real life of lithium iron phosphate battery pack.

Waste lead-acid batteries can be recycled. With the development of new energy vehicles, a large number of waste lead-acid batteries flow into the market, so how to recycle these waste lead-acid batteries? Let's have a look!

At this moment, if the old battery is lead-acid that someone will recycle it at high price, but if it’s lithium battery, no one cares, and he nees to buy a whold new lithium battery. What is it about this ? Listen to the following brief analysis.

The failure of lead acid batteries is the result of many factors, which is determined by the internal factors of the plate, such as the composition of active substances. Crystal form, porosity, plate size, grid material and structure also depend on a series of external factors, such as discharge current density, electrolyte concentration and temperature, discharge depth, maintenance status and storage time. Here are the main external factors.

However, the above phenomenon is not common, and most chargers will not or do not often have similar problems. This kind of charger is not only rare, but also a relatively old one that has been used for many years. The correct way to use the charger is that at the later stage of charging, although most of it has been charged, a small amount of sulfurized substances on the plate are not completely reduced.