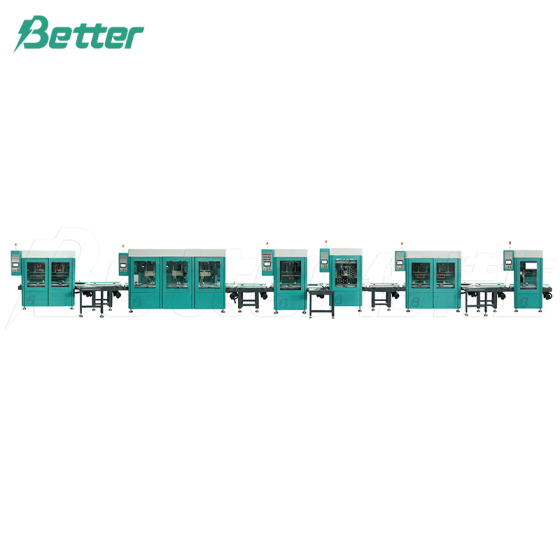

Four Station COS Machine

Four Station COS Machine for Lead-Acid Batteries. Automates bus bar/terminal casting with four-station process (20-40s/time), PLC control, optional tin dipping/copper terminals, and reliable water recycling for efficient, high-quality plate group assembly across automotive, VRLA, and tubular types.

- BETTER

- CHINA

- Information

- Video

Equipment performance

The equipment is used for lead-acid battery bus bar and terminal casting, the best scope for equipment: 12v36ah-200ah battery, those bigger than 12v120ah need twice cast welding.

Operation Process

The first station is to load plate groups.

The second station is to cut and brush the lugs and dip the soldering flux.

The third station is for automatic casting & welding.

The four station is for unloading the plate groups into the container.

Parameter

Production capacity: starting battery 20-22seconds/time; Sealed battery 25-30 seconds/time; Tubular battery 30-40 seconds/time

Distribution requirements: 220V/380V, 3 phase, 50Hz or as required.

Total power: 46.5KW

Electrical configuration: PLC for MITSUBISHI, pneumatic accessories for SMC

Compressed air: 5~6Kg/cm2

Water: soft water 8 liters/min, 25℃ water pressure > 0.15MPa, can be recycled

Lead pot: 1000Kg, easy to load

Size: length 3050*width 3100*height 3400

Weight: 2640Kg

Optional

The second station can add the function of tin dipping.

The third station can add the function of placing copper terminal automatically.

The fourth station can add the automatic function of container insertion (suitable for 12V 36Ah-200Ah battery)