Case Analysis of Double-sided labeling machines in Various Industries

2024-11-06 18:00Introduction

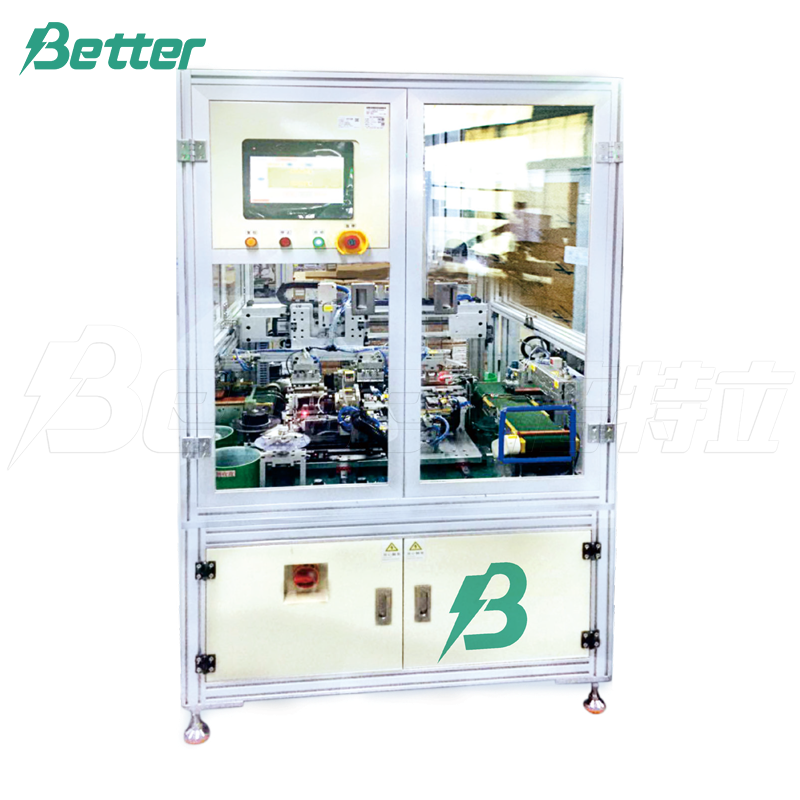

Double-sided labeling machines are efficient and precise automated devices widely used across multiple industries, including electronics manufacturing, food packaging, medical devices, and industrial manufacturing. Their exceptional dual labeling capabilities and flexible adaptability significantly enhance production efficiency and quality assurance in various production lines. This article will analyze specific application cases of Double-sided labeling machines in different industries, providing insights into their multifunctionality and applicability.

I. Application in the Electronics Manufacturing Industry

Case Background:

A company specializing in electronic components needed to apply precise dual-sided labels to capacitors and inductors to ensure correct identification and stable performance during assembly. Previously, the company used traditional single-sided labeling machines and manual labeling methods, leading to low production efficiency and misaligned labels.

Application Results:

· Increased Production Efficiency: The introduction of the Double-sided labeling machine improved labeling efficiency by approximately 60%, significantly reducing production time. The fully automated operation minimized manual intervention, streamlining the production process.

· Reduced Labeling Errors: The machine's high-precision labeling function effectively addressed label misalignment, achieving an accuracy of ±0.1 mm. This greatly decreased rework rates and enhanced product consistency.

· Lower Labor Costs: Automation reduced the need for extensive manual labor in label application, directly lowering labor costs and minimizing production losses due to human error.

II. Application in the Food Packaging Industry

Case Background:

A large food packaging enterprise required dual-sided labeling for its food containers, including product information labels and anti-counterfeiting identifiers. The previous labeling methods could not meet the demands for dual-sided labeling and high-speed production, severely impacting production efficiency and label adhesion reliability.

Application Results:

· Enhanced Production Line Speed: The Double-sided labeling machine completed the labeling of both sides of the container in a single step, reducing production processes. The machine can label over 1,000 containers per hour, significantly improving the overall speed of the packaging line.

· Ensured Label Adhesion Quality: Given the high standards for label adhesion in food packaging, the machine's high-pressure application and precise positioning features ensured labels remained attached during storage and transport, complying with food safety and quality standards.

· Improved Brand Image: The neatly applied labels enhanced the overall quality of the packaging, strengthening the product's market competitiveness and brand image.

III. Application in the Medical Devices Industry

Case Background:

A medical device company needed high-standard labeling for its products, including product descriptions and warning labels. Traditional labeling methods failed to meet the high precision and stability requirements, affecting market compliance and user experience.

Application Results:

· Compliance with Stringent Industry Standards: The Double-sided labeling machine’s high precision and stability ensured that every label was accurately applied in the designated position, meeting the strict compliance requirements of the medical device industry.

· Reduced Defect Rate: The machine’s intelligent control system monitored the labeling process in real-time, promptly correcting any deviations, effectively reducing the occurrence of labeling defects and increasing production quality.

· Improved Working Environment: The introduction of automated labeling equipment reduced the intensity of manual operations, enhancing the working environment, decreasing operator labor intensity, and improving the safety and efficiency of the production line.

IV. Application in the Industrial Manufacturing Industry

Case Background:

An industrial manufacturing company needed to apply dual-sided labels to large metal components for assembly and quality tracking. Traditional manual labeling was time-consuming and prone to misalignment, impacting production efficiency and product traceability.

Application Results:

· High Adaptability in Labeling: The adjustable labeling position and pressure of the Double-sided labeling machine enabled it to adapt to various specifications and shapes of metal components. This flexibility ensured accurate labeling for each part.

· Increased Assembly Efficiency: Clear and accurate labeling information provided precise guidance for subsequent assembly processes, improving overall assembly efficiency and accuracy.

· Data Tracking and Management: The machine supports real-time uploading of labeling data to production management systems, facilitating lifecycle management and traceability, significantly enhancing the company’s production management capabilities.

V. Frequently Asked Questions (FAQ)

Is the Double-sided labeling machine suitable for all types of labels and materials?

Yes, the Double-sided labeling machine can accommodate most common label materials, such as paper labels, PET labels, and self-adhesive labels. The machine's labeling parameters can be adjusted based on the label material and thickness to ensure secure adhesion to different product surfaces.

How can stability be ensured during high-load operation?

The Double-sided labeling machine features an intelligent control system that monitors the operating state in real time. If abnormal loads or other issues are detected, the system automatically adjusts operational parameters or issues alerts. Regular maintenance and inspections are also key to ensuring stability during high-load operations.

Does the machine's versatility across industries affect its specialization and efficiency?

The Double-sided labeling machine is designed for both flexibility and efficiency. Its versatility primarily lies in adjustable parameter settings and multifunctional labeling head configurations, ensuring it does not compromise specialization or efficiency in specific industries. Companies can choose appropriate parameters and functionalities based on their production needs.

How can issues with label detachment during the labeling process be addressed?

Label detachment may result from inadequate label material, insufficient adhesive strength, or improper labeling pressure. Solutions include checking and adjusting the labeling parameters, using high-quality label materials, and ensuring the cleanliness of the label and product surfaces. Regular checks on the labeling head's condition and maintaining the labeling equipment can also effectively reduce label detachment occurrences.

Conclusion

Double-sided labeling machines play a crucial role in various industries such as electronics manufacturing, food packaging, medical devices, and industrial manufacturing, thanks to their efficiency, precision, and flexibility. The specific application cases demonstrate that these machines not only enhance production efficiency and product quality but also help companies achieve automation and standardization in their production processes. For businesses striving for efficient production and stringent quality control, Double-sided labeling machines are undoubtedly an ideal choice to boost productivity and competitiveness.