Lead Dust Purification System

Lead dust purification system applies to purifying the Lead dust in the battery manufacturing process.

- BETTER

- CHINA

- Information

Lead dust purification system

1. Equipment Name:

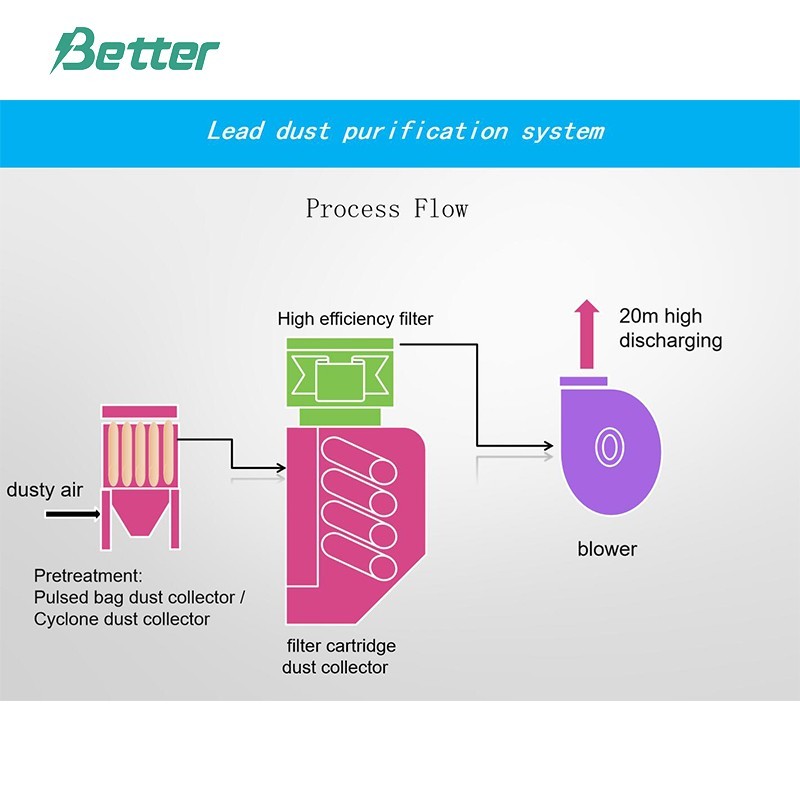

DMC pulse dust collector + CHL type Filter Cartridge Dust Collector+High efficiency dust collector

2. Equipment Composition

The whole system consists of ventilation ducting, DMC pulse dust collector, filter cartridge dust collector,High efficiency dust collector, blower, and electrical cabinet, etc.

Function of the ventilation ducting is to ensure the ventilation of air flow.

Function of the dust collector is: separate the dusty air, the clean air after treatment will be sucked out by the blower and discharged from the chimney.

Function of the blower: the blower is just like the heart of the system, the power source of circulation air flow; the blower is placed behind the dust collector, which will protect the impeller from impact of high-speed and disordered dust particles, improving the service life and reducing the backpressure, ensuring the normal long-term operation. The lead dust will be integrated into the dust collector, and the treated air will be discharged from the chimney via the blower.

3. Equipment Working Principle

3.1 Treatment Method

The plate cutting and brushing area will generate lead dust. We adopt the Filter Cartridge Dust Collector, the filter area is 3~5 times larger than the normal bag filter, and the filter precision can reach up to 0.5 um. It is mainly surface filtration, without going into the filter material. Through pulse solenoid valve spraying, it ensures the service life of the filter cartridge will be more than one year.

3.2 Working Principle

Via the blower, dusty air will enter into the DMC pulse dust collector, with the centrifugal force, the spark and dust in the air will be removed. Then the air will enter into the filter cartridge dust collector from the top air inlet, the dust and air will be separated via all kinds of effect function from the filter cartridge, the dust will be adsorbed onto the filter bags and the air will go up to the upper part through the Venturi-tube. As time goes, more and more dust will be accumulated onto the filter bags, resistance of the filter cartridge will be increased, less air amount will be able to go through the filter cartridge. In order to ensure the dust collector works well, the pulse controller will send out instructions to trigger all control valves in order, the pulse valves will be opened. The compressed air inside the air bags will be jetted to the matching filter cartridges via the Venturi-tube from all holes on the spraying pipes. With the instant reverse function from the airflow, the dust on the surface of the filter cartridges will be dropped off, the filter cartridges achieves regeneration. The dropped dust will be fallen into the dust hopper and discharged outside the dust collector through the dust-discharging system.

3.3 Emission System

The chimney is 15m high from the ground, equipped withφ80 testing hole, which will be closed during at ordinary times.

3.4 Dust Collection System

The lower part of dust collector consists of dust hopper, butterfly valve and dust bucket. According to the dust amount in each station, open the butterfly valve in the bottom of dust hopper at regular intervals, so that the dust will fall off into the dust bucket, move the dust bucket to the solid waste treatment station.

3.6 Emission Standard

According to the standard of 《The Integrated Emission Standard of Air Pollutants》 GB16297-1996, the requirement should be:

Pollutant | Discharging Height | Max. allowed emission concentration |

Lead and its compound | 15m | 0.50mg/m3 |

4. Advantages of the inclined filter cartridge dust collector

4.1 It adopts inclined distribution, therefore, the synchronous dust removal effect during working is good.

4.2 There is dust blocking plate in the dust inlet with the function of buffer and wear resistance, protecting the filter cartridge from direct high-speed impact of dust, therefore, it prolongs the service life of the filter cartridge.

4.3 With 150° inclined drawer type installation, the filter cartridge can be replaced easily. There is transmission part inside the dust collector, the maintenance work will be half reduced. For generalized dust, the filter cartridge can be long-term used without replacement, saving time and a lot of maintenance cost compared with the filter bag.

4.4 Module combination, the capacity can be changed any time.

4.5 The capacity can be enlarged by adding dust collecting unit, without too much modification to the original dust collector.

4.6 By using the filter cartridge, the filter material arrangement density is large, inside the small volume there is large filtration area, the filtration area is 3~5 times larger than the normal filter bag, therefore, the filtration speed and system resistance is reduced, the running cost is also reduced, which saves energy. The low filtration speed also reduces the flow’s destructive impact to the filter material, which prolong the service life of the filter cartridge.

4.7 The key component (like pulse valve) which affects the main performance adopts famous brand, service life of its membrane (wearing part) is more than 1 million times.

5. Equipment Parameter

5.1 Blower

Air volume: 30,000m3/h Static pressure: 3,400Pa Power: 55KW Quantity: 1pc

5.2 DMC pulse dust collector

Model: DMC-120-IV Air volume: 30,000m3/h Velocity of filtering: 2-3m/min Filter bag number: 120pcs Filtering area: 156m2 Filter type: Φ 120 × 4000mm Filter bag material: 650g / m2 high strength and low extensibility needle felt Dust removal efficiency: 99% Equipment resistance : 1000 - 1500Pa Compressed air pressure: 0.5 to 0.7MPa Material: A3 steel Quantity: 1pc

5.3 CHL inclined type filter cartridge dust collector

Model: CHL-3-48 Air volume: Q=30,00m3/H Velocity of filtering: 0.85m/min

Filter cartridge quantity: 48pcs Filtering area: 624m2

Filter cartridge model: Φ350*660mm Material: HV filter materiall

Efficiency of dust collection: 99.97% equipment resistance: 1000-1500Pa Quantity: 1pc

5.4 High efficiency dust collector

Model : GX-30 Air volume: 30,000m3/h Velocity of filtering: 0.85m/min Qty. of efficient filter elements: 12pcs Filter material: imported high efficiency glass fiber High efficiency filter element size: 610mm × 610mm × 290mm Height Filter level: ≧99.99%@0.3um

5.5 Chimney

15m high from the ground, fixed with protective frame; Equipped with independent detection platform and detection port; Diameter: Φ900mm Material: A3 steel Quantity: 1pc