Inert Gas Oven (Oxygen Free Drying Oven)

Inert Gas Oven (Oxygen Free Drying Oven),One time operation can be achieved from retrieval of plates from the forming tank to drying, For positive plates, it provides different factory setting for low temperature drying environment drying environment to ensure the material on the plate won't be changed or deactiveted. It greatly enhances the dry charged ability and its lifetime.

- BETTER

- China

- Information

1.Feature

*Entirely oxygen free drying so that there will not be any oxidation on the plate during drying process allowing and excellent function of engine starting.

*Only 20% of manpower is required to operate our advanced drying method compare to traditional dtying method, therefore the overall efficiency is enhanced greatly.

2.Performance

*Drying capacity per batch load is approximately 3000~4000 panel plates (60 min),Drying Time:90 min per batch; drying Temperature:120°C.

*Simple operation: One time operation can be achieved from retrieval of plates from the forming tank to drying.

*Combustion system:Adopt first class

parts from US North American factory to ensure the most precise combustion and stable pilot fire.

*Water cooling system: Adopt hignly efficient circulating cooling system with large dehumidifying net to ensure the best drying performance in the shortest amount of time.

3.Plate characteristics after drying

*Water content is less than 0.1%

*PbO increase rate is less than 1%

*PbO content is less than 3%

*After drying plates in the inert gas oven, the lead content is extremely high and therefore it gives maintenance-free battery or dty charged battery supreme product performance.

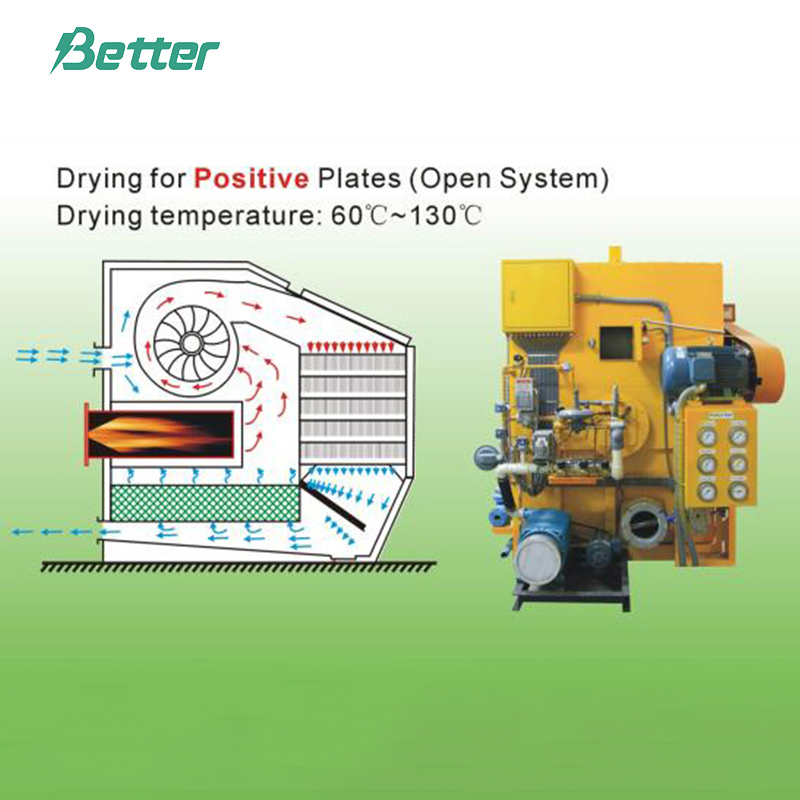

4.Capable of drying positive plates

*For positive plates, it provides different factory setting for low temperature drying environment drying environment to ensure the material on the plate won't be changed or deactiveted.It greatly enhances the dry charged ability and its lifetime.