Gel Mixing Machine for battery

The operation interface is safe and convenient. All these advantages greatly reduce the labor intensity of workers and improve product quality.

- BETTER

- China

- Information

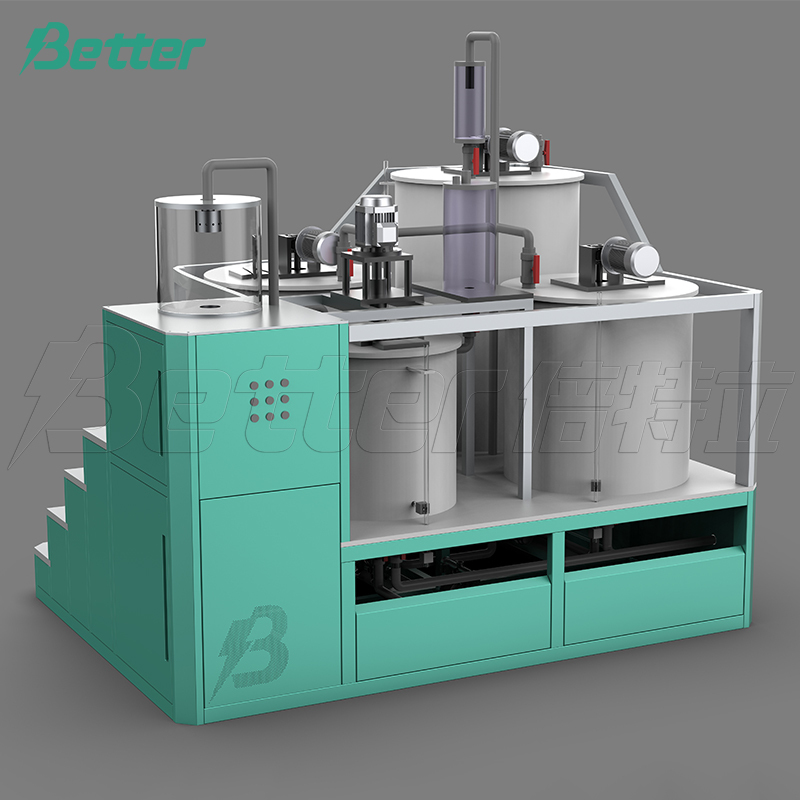

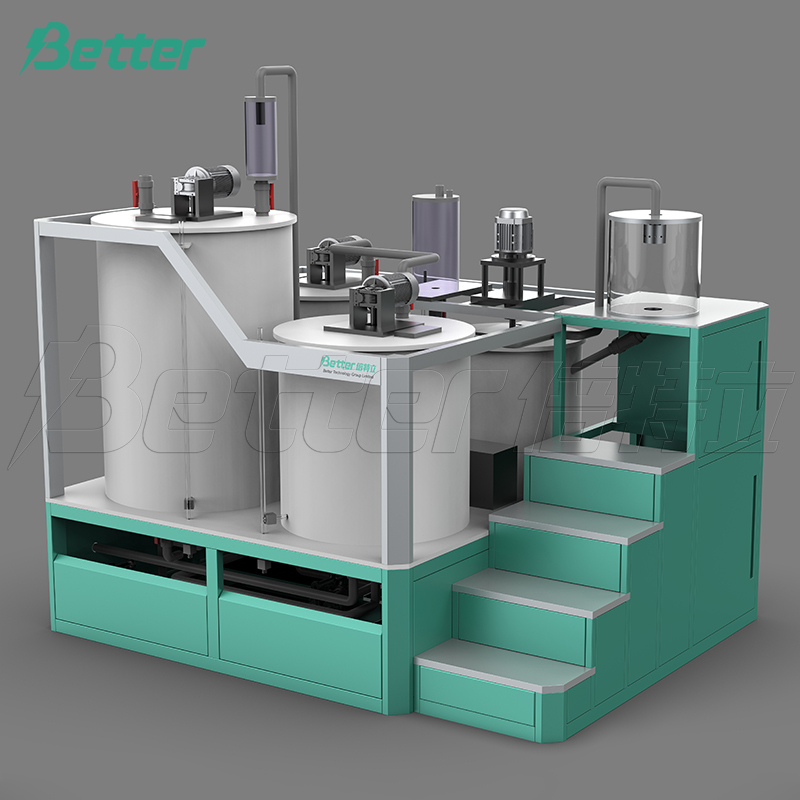

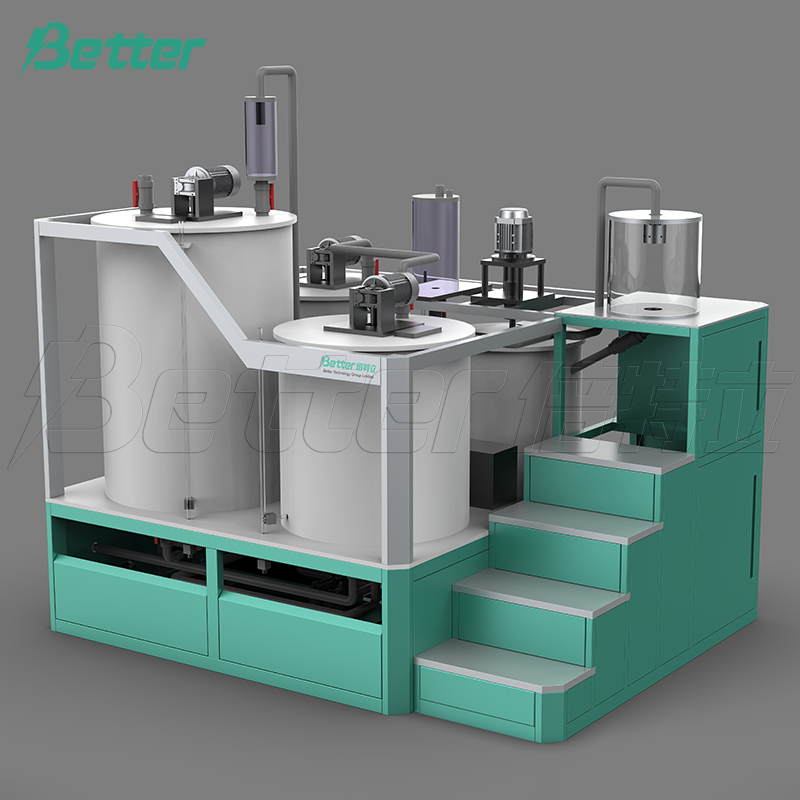

Gel Mixing Machine

This machine is a semi-automatic gel mixing machine, which is divided into high-speed mixing barrels, low-speed mixing barrels, and acid-adding barrels. The wall of the mixing barrels is a multi-layer structure, which has the function of cool and heat insulation. High and low speed mixers make the mixture fully stirring. The operation interface is safe and convenient. All these advantages greatly reduce the labor intensity of workers and improve product quality. The electrical appliances of this machine are directly controlled by buttons, the operation interface is simple and easy to understand, and has the characteristics of high reliability and so on.

Main technical parameter:

1. Application range: lead acid battery

2. High-speed mixing barrels: 2800r/min

3. Capacity of high-speed mixing barrels: Standard 0.3m3 (can be customized according to customer’s requirement)

4. Capacity of low-speed mixing barrel: Standard 0.6m3 (can be customized according to customer’s requirement)

5. Acid-adding barrel: 350-500kg

6. Main power: AC400V50HZ

7. Machine dimension: 2100*1000*2300mm

8. Production capacity: 200L/40min

9. Gel temperature when mixing complete: room temperature / normally 30 degree

Operation:

1. Manually mix the silica powder and water with the proper ratio, add it to the mixing barrel A through the pipeline, start the motor and wait until it stirs well.

2. After opening the valve of barrel B or C, the pressure pump will pump the well stirs mixture from barrel A into the corresponding mixing barrel (barrel B and barrel C is loading with different mixing ratio mixture) for temporary storage, start the motor and continue the stirring.

3. Open the valve of the corresponding mixing barrel, pump into barrel D and mix with acid. After fully stirring, pump to the gel filling machine by the diaphragm pump.

4. There is a drain under each mixing barrel, which is used when cleaning the mixing barrel. Please close the valve when working.