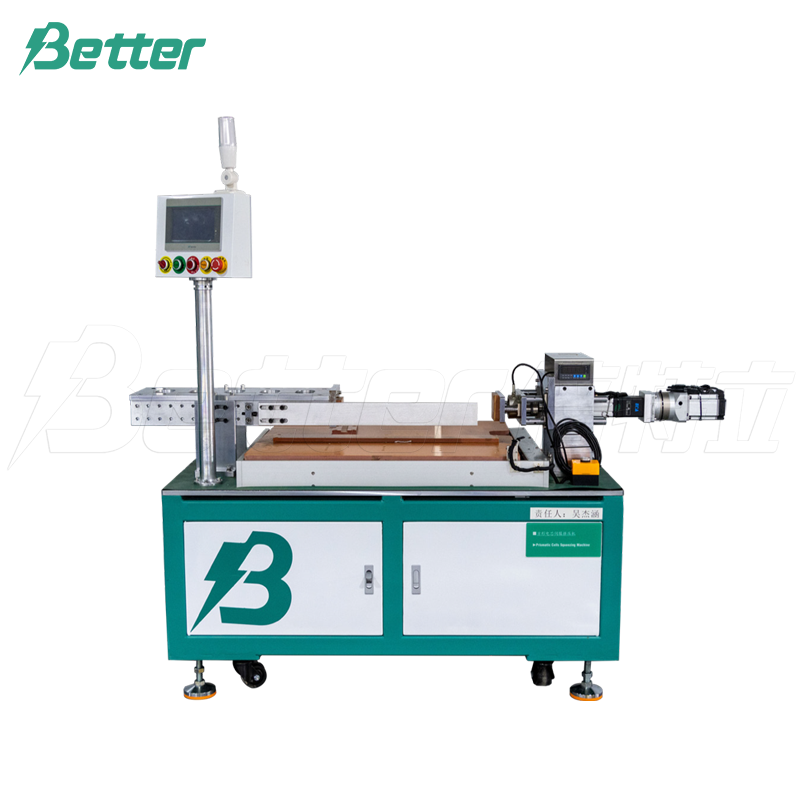

extruder producing large square aluminum shell batteries

Due to tolerances in the dimensions of the incoming battery cels and other bundling methods, the standard dimensions ofthe module cannot be auaranteed: Batch standardized size reauirements can be obtained through extrusion of this unit.

- Information

Function Features

1.Due to tolerances in the dimensions ofthe incoming battery cells and other bundling methods, the standard dimensions ofthe module cannot be guaranteed; Batch standardized size reguirements can be obtained through extrusion of this unit.

2.After the extrusion equipment detects that the battery cells have stopped, the clamping mechanism moves the unboundbatery cells on the wire body to the extrusion position for electric extrusion (about 1T position extrusion pressure electriccylinder),. The pressure can be freely set parameters and extrusion speed, and the pressure is feedback by sensors to achieveaccurate and balanced pressure standards. After extrusion, the size consistency of the battery module is good.

3.After the extrusion is completed, the steel/aluminum strips are manually tied and the extrusion pressure is released. Thenthe clamping cylinder transports the tied battery cells back to the wire body.

Extrusion process description

| Embedded steel strip | Cell stacking | extrusion | Steel strip sleeve | Pinch online |

Technical Parameter

| Single unit efficiency | Compatibility range | compatible length | Single machine power |

| 5PPM | 50-280AH | 400-650mm | 2.0KW |