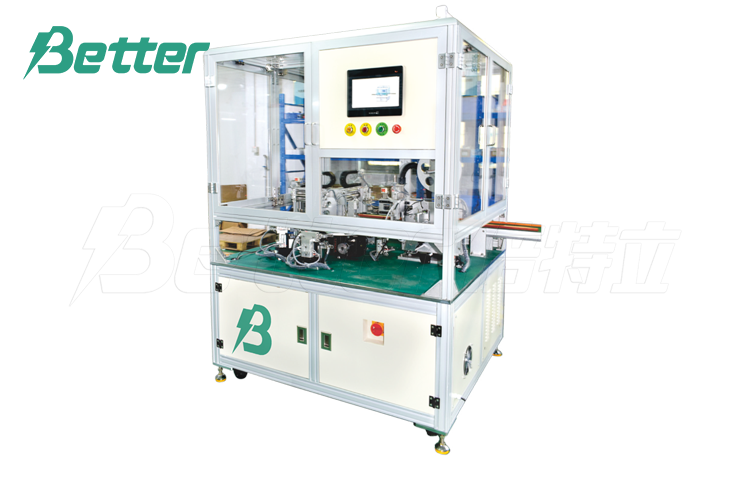

Side Glue Machine: Detailed Explanation of Key Performance Parameters

2024-10-19 18:00When selecting a side glue machine, understanding the key performance parameters of the equipment is essential to ensure the right choice. Different production needs correspond to different equipment specifications. This article will provide a detailed explanation of the key performance parameters of side glue machines, helping enterprises make more informed decisions.

Equipment Size and Applicable Battery Specifications

The size of the side glue machine and its applicable battery specifications are the first factors to consider when making a selection. The equipment size must match the available space on the production line while also being able to handle the battery specifications primarily produced by the enterprise. Common side glue machines can accommodate battery dimensions ranging from 40-120 mm in length, 35-100 mm in width, and 3-10 mm in thickness. When choosing, enterprises should ensure that the equipment's size specifications align with their production requirements.

Gluing Precision

The precision of the gluing process directly impacts the quality of battery packaging. High-precision side glue machines are typically equipped with intelligent vision recognition systems, achieving gluing errors within ±0.3 mm. The higher the gluing precision, the better the uniformity and aesthetic appeal of the packaging. Therefore, for enterprises with high packaging quality requirements, selecting high-precision equipment is crucial.

Operating Speed

The operating speed of the equipment determines the efficiency of the production line. The speed of side glue machines can usually be adjusted to meet different production needs. Generally, the operating speed should match the pace of the production line, ensuring it does not become a bottleneck. High-speed machines can significantly enhance production efficiency but must also consider the stability of the equipment and the quality of the gluing.

Ease of Operation and Intelligence

The ease of operation and level of intelligence of side glue machines are also important considerations when making a selection. Modern equipment often features a touchscreen interface and intelligent control systems, allowing operators to easily adjust parameters and monitor equipment status through a simple interface. Highly intelligent machines reduce operational complexity and improve the flexibility of the production line.

Equipment Stability and Maintenance Requirements

The stability of the equipment and its maintenance requirements directly influence the continuity of production and production costs. When selecting equipment, priority should be given to machines with mature designs and reliable components to ensure stability during long-term operation. Additionally, the maintenance needs and difficulty level of the equipment will affect the daily operational costs of the enterprise. Machines that are easy to maintain can reduce downtime and increase the effective working time of the production line.

Conclusion

When choosing a side glue machine, enterprises need to consider multiple key performance parameters, including equipment size, gluing precision, operating speed, level of intelligence, and maintenance requirements. Only by selecting equipment that meets their production needs can enterprises truly harness the advantages of side glue machines in their production lines, resulting in higher efficiency and better packaging quality.