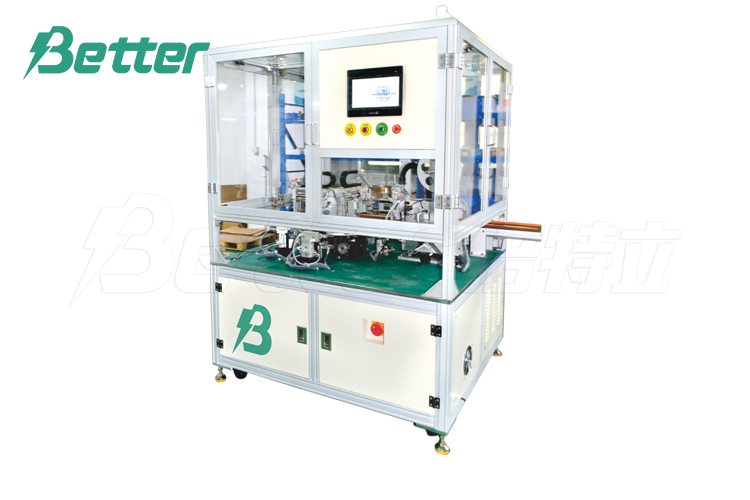

How to Enhance the Automation Level of Battery Production Lines with Side Adhesive Machines

2024-09-11 18:00In the electronics manufacturing industry, automation has become a key factor in improving production efficiency and product quality. Traditional manual operations are not only inefficient but also prone to quality issues. As a highly efficient automated device, the side adhesive machine has brought significant changes to battery production lines. This article explores how side adhesive machines can help companies enhance the automation level of their production lines.

Improving Production Efficiency

The side adhesive machine significantly reduces the time required for battery packaging through fully automated processes. The machine continuously performs steps such as automatic positioning, feeding, adhesive application, pressing, and discharging without human intervention. This automated operation not only eliminates time delays caused by manual handling but also maintains a stable production rhythm, resulting in a substantial increase in hourly output.

Reducing Human Errors

Manual operations are often susceptible to errors such as inaccurate adhesive application, missed spots, and positional deviations. These human errors not only affect the quality of battery packaging but also increase the rework rate, wasting time and materials. The side adhesive machine uses an intelligent visual recognition system to precisely locate the adhesive application position on each battery, ensuring consistency and accuracy. By reducing human errors, companies can significantly lower defect rates and improve the overall pass rate of the production line.

Enhancing Quality Control

The introduction of automated equipment allows every step of the production line to be monitored and optimized. The side adhesive machine is equipped with real-time monitoring and alarm systems that immediately alert operators in case of anomalies. This real-time feedback mechanism enables the production line to make quick adjustments, preventing the occurrence of batches of defective products. Additionally, automated equipment can store production data, facilitating subsequent quality analysis and improvement.

Saving Human Resources

With the rising cost of labor, companies are increasingly focused on how to reduce human resource investment while maintaining production efficiency. The automation features of the side adhesive machine can significantly reduce the need for manual labor on the production line, thereby lowering labor costs. Furthermore, reducing manual operations also minimizes occupational risks for employees during the production process, enhancing workplace safety.

Adapting to Diverse Production Needs

In the production process, different types and specifications of batteries often require different packaging methods. The side adhesive machine features flexible parameter adjustment capabilities, allowing it to quickly switch between different adhesive settings based on production requirements, adapting to a variety of production tasks. This flexibility not only enhances the production line’s responsiveness but also reduces downtime caused by equipment changes or manual adjustments.

Conclusion

By introducing side adhesive machines, companies can transition from traditional manual operations to modern automated production. Automation not only improves production efficiency and product quality but also significantly reduces labor costs, bringing greater economic benefits to enterprises. For companies seeking efficient, precise, and flexible production, side adhesive machines are undoubtedly an ideal choice for enhancing automation levels.