The core tool for battery quality testing: performance testing machine

2024-09-18 18:00Table of Contents

· Introduction

· Product Features and Technical Advantages

o Functional Characteristics

o Core Technical Parameters

· Operation Process and User Guide

· Extensive Application Scenarios and Solutions

o Battery Manufacturing Industry

o PC Board Inspection

o Automated Production Lines

o Electronic Component Quality Control

· Practical Use Cases

o Scenario 1: Battery Manufacturing Line

o Scenario 2: Electronic Component Production Line

· Future Development and Market Outlook

· Frequently Asked Questions (FAQ)

· Conclusion

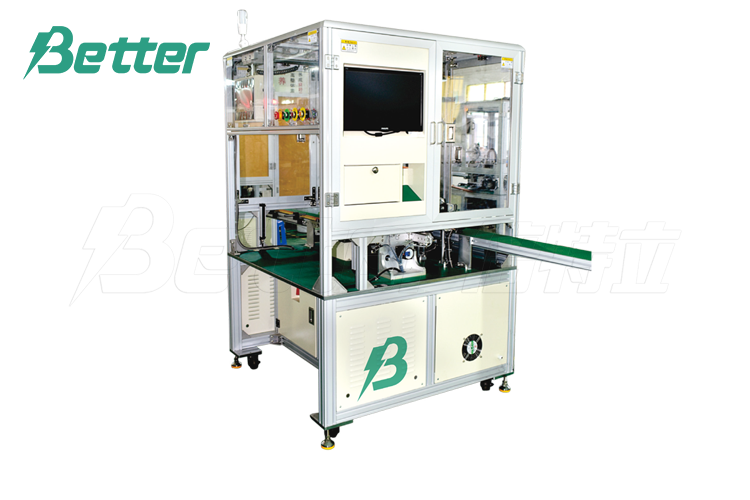

Product Overview

In modern electronic device manufacturing, the quality of batteries and PC boards directly determines product performance and longevity. The performance testing machine is specifically designed to test these critical components, providing comprehensive evaluations of battery and PC board performance to ensure they meet strict quality standards. This article will detail the functional features, technical parameters, application scenarios, and the vital role of performance testing machines in modern manufacturing.

Product Features and Technical Advantages

Functional Characteristics

·

Multi-Functional Comprehensive Testing: The performance testing machine can conduct multi-dimensional performance tests on batteries and PC boards, including resistance, voltage, short circuit, and discharge tests, ensuring that all products meet comprehensive quality standards.

·

·

Fully Automated Detection: The device utilizes robotic arms and CCD vision systems to achieve fully automated operation, from feeding to testing and sorting, without requiring human intervention, significantly boosting production efficiency.

·

·

High-Precision Detection: Equipped with high-precision sensors and intelligent algorithms, the performance testing machine can detect even the smallest performance variations in batteries and PC boards, ensuring that every product meets the strictest quality standards.

·

·

Data Management and Traceability: The machine includes a built-in data management system that records each test result in real time and generates detailed test reports. This data traceability supports quality management and helps optimize production processes.

·

·

Adaptability to Multiple Specifications: The machine can accommodate various sizes and types of batteries and PC boards. Users can quickly adjust the equipment through simple parameter settings to meet different production requirements.

·

Core Technical Parameters

· Transmission Size (Tj/mm): L:40-120, W:35-90, T:3-10

· Detection Accuracy: Simulated test accuracy of ±0.5%

· Air Pressure Requirement: 0.5 MPa

· Operating Environment Temperature: 0~50°C, Humidity: 30%~95%

· Equipment Power: 3 KW

· Power Requirements: 220V 50Hz

· Detection Speed: 1200 PCS/H

· Equipment Dimensions: 1200 × 1290 × 1990 mm

Operation Process and User Guide

To ensure the optimal operation of the performance testing machine, follow these standard procedures:

1. Product Feeding: Use the automated feeding system to send batteries or PC boards into the testing machine, where the equipment automatically begins the testing process.

2. Performance Testing: The device conducts performance tests based on preset standards and records the data in real time.

3. Data Analysis and Sorting: The system automatically analyzes the test data and sorts out products that do not meet the standards, ensuring that only qualified products proceed to the next stage.

4. Maintenance and Debugging: The machine features self-diagnosis and remote maintenance capabilities, allowing users to monitor the equipment status remotely and perform online debugging and maintenance.

Extensive Application Scenarios and Solutions

Battery Manufacturing Industry

In battery manufacturing, the stability and consistency of battery performance are crucial. The performance testing machine conducts comprehensive performance tests on battery production lines to ensure every battery meets design specifications, enhancing product reliability.

PC Board Inspection

The performance testing machine can quickly and efficiently test various performance indicators of PC boards, making it ideal for high-precision, high-reliability electronic product production lines, ensuring that PC boards meet optimal quality standards.

Automated Production Lines

The fully automated operation of the performance testing machine allows seamless integration into modern automated production lines, boosting production efficiency, reducing human intervention, and lowering production costs.

Electronic Component Quality Control

In electronic component manufacturing, the performance testing machine conducts comprehensive tests on key components, helping companies improve product quality and reduce defect rates.

Practical Use Cases

Scenario 1: Battery Manufacturing Line

In a large battery manufacturing plant, the performance testing machine is used to inspect the production of new lithium batteries. The machine’s efficient testing capabilities ensure the stability of each battery’s performance, significantly enhancing product quality and helping the plant maintain a leading position in a highly competitive market.

Scenario 2: Electronic Component Production Line

At a renowned electronic component manufacturing facility, the performance testing machine is used for PC board inspection. The device’s high-precision testing and intelligent data analysis capabilities help the company improve production efficiency, reduce defect rates, and minimize rework and waste.

Future Development and Market Outlook

As the demand for high-performance electronic products continues to grow, the performance testing machine will play an increasingly important role in the future. With ongoing technological advancements, the equipment will further improve in detection accuracy and speed while adding more intelligent features, such as automatic optimization of testing processes and real-time monitoring of production line conditions. This will provide stronger support for quality control in the electronics manufacturing industry.

Frequently Asked Questions (FAQ)

1. Which industries are suitable for performance testing machines?

· The device is suitable for battery manufacturing, PC board inspection, automated production lines, and electronic component quality control, among others.

2. What is the detection accuracy of the equipment?

· The performance testing machine has a detection accuracy of ±0.5%, meeting the requirements of high-precision manufacturing industries.

3. Are maintenance requirements high for the equipment?

· Maintenance is relatively simple, primarily involving regular cleaning of sensors, checking system calibration, and updating equipment software. The built-in self-diagnostic function helps users identify and resolve issues early.

4. Can the equipment accommodate different product specifications?

· Yes, the performance testing machine supports testing of multiple product specifications, and users can adjust detection parameters through simple settings.

5. Does the equipment support remote monitoring and maintenance?

· Yes, the device supports remote monitoring and maintenance, allowing users to view the equipment status in real-time over the network, reducing maintenance costs and downtime.

Conclusion

With its high precision, multi-functionality, and full automation, the performance testing machine has become an essential quality inspection device in the battery, PC board, and electronic component manufacturing industries. As market demand for high-performance products increases, performance testing machines will play a key role in more industries, providing companies with stable and efficient quality assurance.