Intelligent development of Chinese manufacturing enabled lead-acid battery manufacturing industry

2021-09-09 09:44Profit from the rapid development of China's economy and the rise of China's manufacturing industry, the development of Lead-acid battery manufacturing equipment has also entered the world's advanced ranks. China's lead acid battery manufacturing equipment is gradually well-known overseas, all over the world. Especially under the in-depth implementation of the "Belt and Road Initiative national development strategy,", in recent years, Vietnam, India, southeast Asia, South Asia, the Middle East countries and regions such as lead-acid battery industry in the development of the rise of the originally dominated by the United States, Italy, Japan, South Korea manufacturing of lead-acid battery production equipment has gradually turned to tilt, made in China The demand form of equipment also gradually develops from unitary to integrated, integrated and systematic.

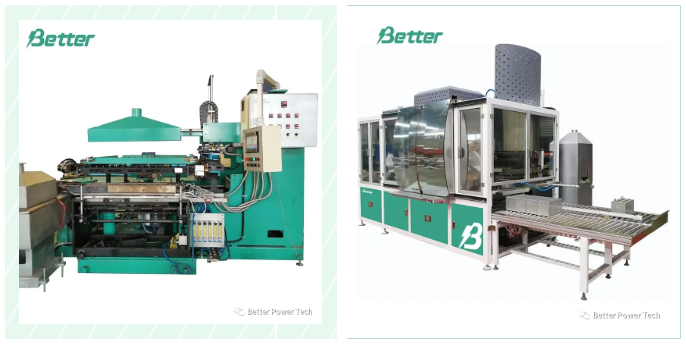

complete battery manufacturing machines,during installing and comissioning.

As an enterprise that has been deeply involved in the lead-acid battery manufacturing industry for more than ten years, Better has seized the development opportunities of the times and conformed to the general development trend of the industry. From a single lead-acid battery manufacturing equipment supplier in the past, it has developed An innovative enterprise integrating complete set of equipment, installation and commissioning, technical training and guidance, after-sales guarantee and other general contracting system integration services, is committed to promoting the deep integration of lead-acid battery equipment manufacturing and service industries, and building new core competitive advantages.

We are well aware that innovation is the core driving force for an enterprise to move forward, and market acceptance is an important criterion for testing the vitality of products. As far as the lead-acid battery manufacturing industry is concerned, the lead-acid battery manufacturing industry is driven by innovation, paying close attention to market demand and the development of cutting-edge technology, increasing investment in product R&D and design, and actively advancing the pace of industry automation and intelligent manufacturing, which is the current lead-acid battery manufacturing industry welcomes An important move to challenge.

In last few years, the impetus of the lithium-ion battery technology, customers personalized needs of growing under the multiple challenges, such as combination of products to the high-end towards situation need, lead-acid battery manufacturing industry in our country at the forefront of technology, is also to strengthen the research and application of new product technology, to overcome a batch of product based on generic technology, accelerate the development of the intelligent transformation. For example, some high-end equipment has made breakthroughs, continuous casting and rolling, drawing (punching) net integrated plate manufacturing system; Automatic casting and welding line for small dense power battery; Automobile battery high-speed CNC assembly line; Integrated automatic acid circulation system; Rapid pulse charging technology, etc.

Plate Strap Casting Machine(COS)

In addition to the technological innovation and improvement of lead-acid battery manufacturing equipment, the subsequent installation, commissioning, overhaul, and maintenance of the equipment also have high technical requirements, and each step requires professional technical personnel to operate. Therefore, this is a buyer's market with a long industrial service chain. In addition to ensuring that the equipment has the basic characteristics of durability, the technical content of the service team is also very demanding. Better has been deeply involved in the industry for more than ten years. It has established a senior equipment and battery manufacturing technical team, supply chain development team, and quality management team to conduct technical analysis on each product, formulate Better standards and output product standards. Strictly control the link, carry out strict quality inspection before product shipment, from design, production to delivery, every detail is checked to ensure product quality. At the same time, it can provide customers with perfect project management services and solutions, solve various technical problems in a timely and accurate manner, and are widely recognized and supported by customers.

China intelligent Manufacturing 2025, German Industry 4.0... Under the background of the era, a new round of scientific and technological revolution has arrived, and intelligent manufacturing has increasingly become the trend and core of the development of the future manufacturing industry, but there is still a long way to go.As a core practitioner in this industry, what we can do is to keep our feet on the ground, do a good job of equipment, provide a good service, ensure product quality, improve labor productivity for customers, and create more value-added services.