Enhancing Battery Production Line Automation with Side gluing machines

2024-09-26 18:00Analysis of the Application Advantages of Side gluing machines in Soft Pack Battery Packaging

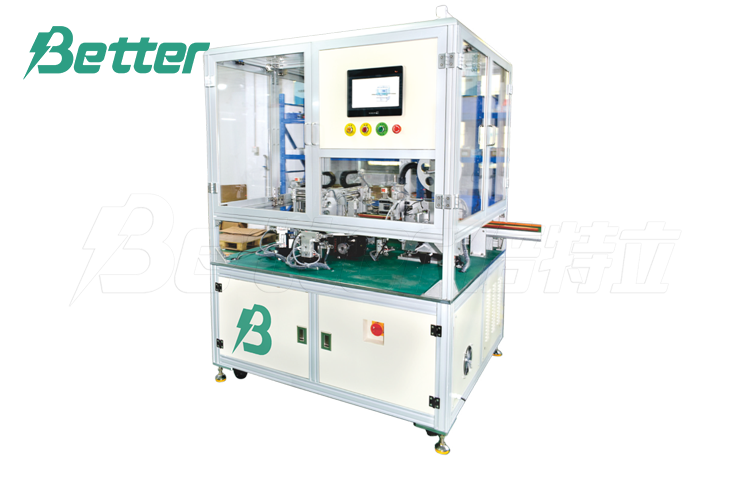

Soft pack batteries are widely used in electronics and new energy sectors due to their lightweight, flexibility, and high safety features. However, the packaging quality of soft pack batteries directly affects their performance and lifespan. As a crucial device in soft pack battery packaging, the Side gluing machine provides strong support for improving packaging quality and production efficiency. This article delves into the advantages of using Side gluing machines in soft pack battery packaging.

Enhancing Packaging Quality

The packaging of soft pack batteries demands strict uniformity and tightness in adhesive application. Side gluing machines utilize intelligent visual recognition systems and precise robotic arms to achieve high-precision adhesive application, ensuring each battery is sealed tightly and uniformly. Compared to manual operations, machine-based adhesive application effectively avoids common issues such as bubbles, wrinkles, and misaligned adhesive placement, thereby enhancing packaging quality and extending battery life.

Improving Safety

The quality of battery packaging is directly related to the safety of the battery. Side gluing machines precisely control the adhesive placement and pressure, ensuring a tight seal that minimizes the impact of external environments on the battery’s internal components, thereby enhancing battery safety. This is particularly crucial in high-safety-demanding fields such as electric vehicles, where the use of Side gluing machines can significantly reduce battery safety risks.

Boosting Production Efficiency

Traditional manual adhesive application is not only inefficient but also prone to errors that lead to rework, affecting production schedules. The automated process of Side gluing machines allows for efficient, continuous production, significantly boosting production efficiency. Features like automatic feeding and discharging reduce the time batteries spend on the production line, optimizing the overall production flow and substantially increasing the overall efficiency of the production line.

Reducing Production Costs

The efficiency and stability of Side gluing machines not only improve production efficiency but also effectively reduce production costs. By minimizing manual operations, companies can save significantly on labor costs. Additionally, the machine’s high-precision adhesive application reduces material waste and defect rates, further lowering production costs. For large-scale production enterprises, the cost-saving benefits of Side gluing machines are particularly notable.

Adapting to Various Battery Specifications

In real-world production, different sizes of soft pack batteries often require different packaging methods. Side gluing machines can quickly adapt to varying battery packaging requirements by adjusting parameters. This flexibility allows the equipment to be widely used across various soft pack battery production lines, offering companies a broader range of production options.

Conclusion

The application of Side gluing machines in soft pack battery packaging not only improves packaging quality and safety but also enhances production efficiency through automation and reduces costs. For companies striving for high-quality and efficient production, Side gluing machines are undoubtedly the ideal equipment for optimizing soft pack battery packaging processes.