- Home

- >

News

The technical parameters of the battery plate curing and drying chamber have a significant impact on the quality and performance of batteries. This article will take you through the challenges of these technical parameters, explore the possibilities of optimization, and reveal the opportunities and challenges within.

In the battery manufacturing industry, technological innovation is key to driving industry development. This article will introduce how the battery plate curing and drying chamber leads the battery manufacturing industry to new heights through technological innovation.

In the field of battery manufacturing, the battery plate curing and drying room is a critical production link. Its technical parameters and performance characteristics directly affect the quality and performance of the battery. This article will provide an in-depth analysis of the technical parameters of the battery plate curing and drying room and reveal how it aids in the manufacture of high-quality batteries.

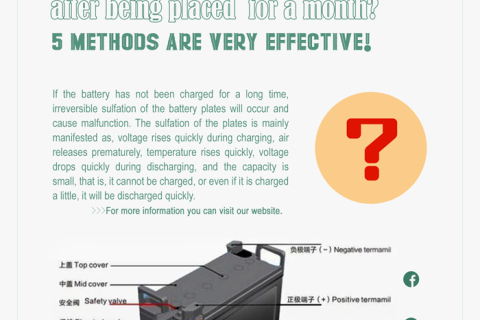

It depends on the degree of sulfurization of the battery plate. Severely sulfurized batteries can only be scrapped, if the sulfurization is slight, they can be charged after desulfurization, which is a method of troubleshooting charging.

How to prevent the battery from being "starved to death" after being placed for a period of time?