News

Pursuing energy of the sun, we believe that diligence is the charm. As a leading new energy company, lately Better Technology Group Limited (Better Tech Group for short) celebrated the Mid-Autumn Festival with the 3rd Points-Gifts Party and the Mooncake Gambling Recreation to appreciate the fine Chinese ancient cultures and to send thanks to the hard work of all corporate staff, to enrich staff’s recreational life and to create a bonding moment for everyone in Better Tech Group.

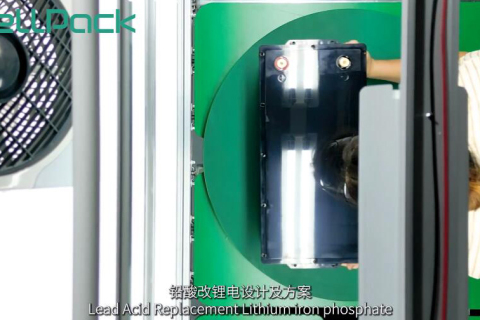

Lithium-ion battery replacement solution for lead-acid battery introduced in this article is one of the core businesses of Better Group. We offer ODM/OEM customization services and tailor-made integrated battery manufacturing solutions in terms of the needs of different customers in different scenarios such as motorcycle/forklift/RV/ship/new energy vehicle batteries, emergency power supply, solar energy base station and other application scenarios.

The Tanzanian delegation spoke highly of Better Group's internationalized development strategy and business model, and said that Tanzania and Better Group shared a great cooperation potential in the fields of photovoltaic energy and battery intellectual manufacturing. They expected there would be more possibilities to cooperate with Better Group in business programs and to inject new energy into development and improvement of Tanzania’s energy sector.

Recently, according to the regulations of "Notice of Xiamen Municipal Bureau of Industry and Information Technology on the Issuance of the Management and Support for Xiamen's Excellent Small and Medium-sized Enterprises" (Xiamen Municipal Bureau of Industry and Information Technology, Regulation File [2023] No. 2) and "Notice by Xiamen Municipal Bureau of Industry and Information Technology on the Recognition to Xiamen's Excellent Small and Medium-sized Enterprises for the Year of 2023", Better Technology Group Limited was among the list.

With the theme of "New Energy Zero Carbon Solution Creates Green Future", this activity was aimed to explore the new model of ecological and sustainable development and the new path towards realizing the dual-carbon goal through the integration of photovoltaic power, energy storage technology and multi-industry integrated development modes so as to promote the global sustainable development and create a green zero-carbon future with the empowerment of science and technology and the upgrading of energy sources.

"We are looking for some cooperation opportunities in foreign markets, hoping to learn from the successful experience of Better Group in the international market as well as the innovative developments of new energy industry overseas, exploring the new cooperation patterns in domestic industries, and joining hands with the upstream and downstream enterprises of the industrial chain to expand into the international market."

Better Technology Group Limited (hereinafter Better Group) was invited to the 23rd China International Fair for Investment and Trade (CIFIT) and Jimei District Investment Conference on September 8th. Better Group President Wei Yanping and her board of directors were invited to attend the event, and released the company's latest core service—New Energy Zero Carbon Solution at the New Energy Sub-forum, which attracted a lot of attention from industry insiders.

On September 6th, at the invitation of the Embassy of the Republic of Botswana in China, Wei Yanping, the President of Better Technology Group Limited (hereinafter Better Group) attended the Botswana Trade and Investment Forum.

Better Group extends a sincere invitation to all representatives and partners to join us in the 20th Asian Battery Conference and Exhibition, Booth No. 44&29.

In recently, Yu Qing, Investment Director of China-Africa Development Fund (abbreviation CADF), Ji Jun, official of Zambia Representative Office, Gao Ran, Senior Manager Assistant of Investment Department, and Li Lujun, Development Director of China Power Investment (Fujian) Power Development Co., Ltd. visited Better Technology Group Limited (Better Group for short). Wei Yanping, President of Better Group, Liu Dewei, General Manager of Better Group, and Huang Chao, Operation Director of Better Group, warmly welcomed their arrival and discussed with them about the cooperation patterns and opportunities in the fields of battery manufacturing and photovoltaic energy storage in Africa.