Economic Benefit Analysis of Glue Laminating Machines: A Comprehensive Evaluation from Investment to Return

2024-10-08 18:00Economic Benefit Analysis of Glue Laminating Machines: A Comprehensive Evaluation from Investment to Return

Introduction

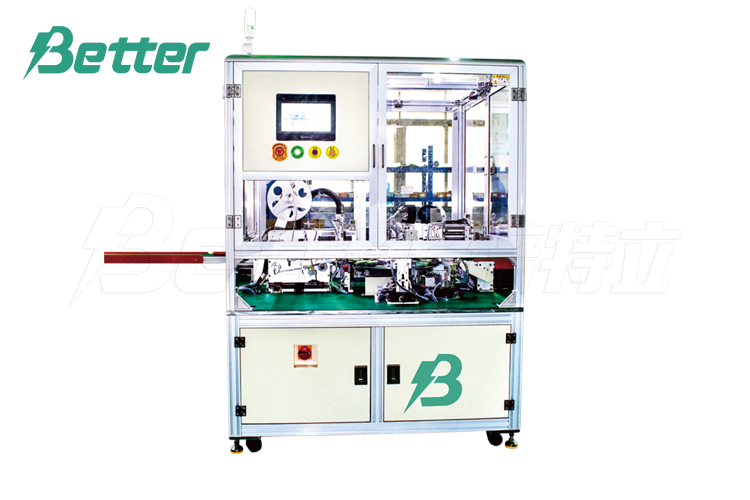

In today’s fiercely competitive market environment, businesses looking to introduce new equipment focus not only on technical parameters and production efficiency but also on investment return rates. Glue Laminating Machines, as highly automated devices, provide significant production efficiency improvements and cost savings for battery manufacturing companies. This article will comprehensively analyze the economic benefits of Glue Laminating Machines from investment costs, operational costs, production benefits, and investment return periods, helping enterprises make informed investment decisions.

Cost Structure Analysis

Equipment Procurement Costs

The procurement cost of a laminating adhesive machine primarily depends on the model, configuration, and required level of automation. The price range of Glue Laminating Machines on the market is quite broad, from basic to high-end models, with prices ranging from hundreds of thousands to millions of yuan. For small and medium-sized enterprises, selecting the appropriate model and configuration can effectively control initial investment costs.

Operating Costs

The operating costs of the equipment mainly include power consumption, maintenance fees, and consumable costs.

Power Consumption: Glue Laminating Machines utilize efficient motors and intelligent control systems, resulting in relatively low energy consumption.

Maintenance Fees: The modular design and high-durability materials of the equipment make daily maintenance simple. Regular maintenance costs mainly involve the replacement of wear parts and routine upkeep.

Consumable Costs: This includes adhesive films and cleaning agents, with intelligent adhesive film usage control reducing material waste.

Labor Cost Savings

The introduction of automated equipment significantly reduces the need for manual operations. Traditional manual adhesive application processes require multiple operators, whereas Glue Laminating Machines can be operated and monitored by just 1-2 technicians. According to practical cases, the introduction of Glue Laminating Machines has allowed enterprises to reduce direct labor costs by over 60%, significantly decreasing training and management expenses.

Production Benefit Analysis

Increased Production Efficiency

Glue Laminating Machines integrate multiple automation functions, enabling continuous operation on the production line and greatly enhancing production efficiency. Typically, the adhesive application speed of the equipment can reach 2 pieces per second, resulting in a production capacity of several thousand pieces per hour. This efficient production means higher output and shorter delivery cycles for enterprises.

Improved Product Quality

The high-precision automated control system ensures the accuracy of each adhesive application, significantly reducing the defect rate. Statistics indicate that the defect rate can be controlled to below 1% after using a laminating adhesive machine, representing an 80% reduction compared to traditional manual operations. This not only enhances the consistency of product quality but also minimizes additional costs incurred from reworking and waste management.

Enhanced Operational Flexibility

The multifunctionality and adjustability of the equipment enable the production line to respond quickly to market demand changes. Whether switching between different sizes of electrode sheets or changing adhesive film types, the laminating adhesive machine can complete adjustments and transitions within a short time, greatly enhancing the operational flexibility of enterprises.

Investment Return Period

The investment return period for introducing a laminating adhesive machine is typically short, depending on the enterprise's production scale and efficiency improvement. Below is a return analysis of a practical case:

Case Analysis:

A battery manufacturing enterprise introduced a medium-sized laminating adhesive machine with an initial investment of 1.5 million yuan. After operation, production efficiency increased by 30%, and annual output rose by 500,000 pieces. Due to reduced defect rates and labor cost savings, the enterprise saves approximately 600,000 yuan annually. Based on these data, the enterprise recouped its equipment investment cost within 2.5 years and achieved significant cost savings and production benefits thereafter.

This rapid return on investment not only enhances the company's cash flow but also provides strong support for its sustainable development. For larger-scale enterprises, the economic benefits and market competitiveness brought by the equipment are even more significant.

Comparative Analysis: Economic Benefits of Traditional Processes vs. Automated Equipment

Compared with traditional manual adhesive application processes, the economic benefits of Glue Laminating Machines are primarily reflected in the following aspects:

Efficiency Advantage: Automated equipment's production efficiency is several times that of manual operations, significantly shortening production cycles.

Quality Advantage: Automated control greatly reduces the defect rate, minimizing economic losses due to quality issues.

Cost Advantage: Although the initial investment in equipment is high, savings on labor costs and increased efficiency result in lower total costs in the long run.

Through comparative analysis, it is evident that while the initial investment for Glue Laminating Machines is higher, they offer significant advantages in production efficiency, product quality, and cost control, making them a key investment for achieving sustainable development in enterprises.

Conclusion

As an efficient automated production device, the laminating adhesive machine brings significant economic benefits to battery manufacturing enterprises. Through detailed analysis of equipment cost structures, production benefits, and investment return periods, it is clear that Glue Laminating Machines can help enterprises significantly improve production efficiency, reduce costs, and maintain a competitive edge in a highly competitive market. For businesses seeking greater competitiveness, investing in Glue Laminating Machines is a choice worth considering.

FAQ

Q1: What is the typical investment return period for a laminating adhesive machine?

A: The investment return period is usually 1-3 years, depending on the enterprise's production scale, efficiency improvements, and the condition of equipment usage.

Q2: Are the operating costs of the equipment high?

A: The operating costs mainly include power consumption, maintenance fees, and consumable costs. Overall, the operating costs are relatively low, and as production efficiency improves, the unit production costs will further decrease.

Q3: What are the long-term economic benefits of investing in a laminating adhesive machine for enterprises?

A: Glue Laminating Machines can significantly improve production efficiency, reduce defect rates, and lower labor costs, providing long-term economic benefits for enterprises. The investment return period is short, making it an important means to enhance competitiveness in the long term.

Q4: Are Glue Laminating Machines suitable for all battery manufacturing enterprises?

A: The equipment is suitable for most battery manufacturing enterprises that require adhesive film application processes, especially for soft-pack batteries. Enterprises should choose the appropriate equipment model based on their production scale and needs.

Q5: How can the investment return rate of the equipment be calculated?

A: The investment return rate can be assessed by calculating the cost savings brought by the equipment (such as labor costs and reduced defect rates) and the economic benefits of efficiency improvements, combined with the initial investment cost. Typically, enterprises can recoup their investment and achieve profitability in a short time.